SMD & BGA Rework

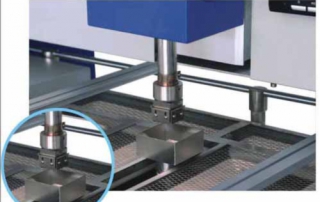

Bga Robot HOT AIR + IR

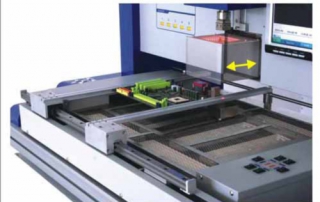

Integrative structure design. The perfect integration of optical aligning, placing mechanism and heating system makes aligning and placing of components on PCB easy and convenient. High automatization. The movement of top heater is controlled by PC(up-and-down moving and lifting after de-soldering of components). Excellent design of PCB clamping; Easy to place and remove PCB. The integration of large-area preheating and sectional hot air heating minimizes temperature differences between BGA packaging surface and soldering joint. It not only prevents PCB from being distorted, but also shortens BGA soldering time to reduce risk of damaging PCB and BGA components. Use large power brushless DC fan; Temperature controlled by closed loop sensor and zero triggering; Large generation of hot air. Control heating of bottom infrared pre-heater separately. PCB bracket adjustable and motor controls adjustment. Program can be set to control top and bottom hot air temperature. Powerful fan cools bottom heating area rapidly.

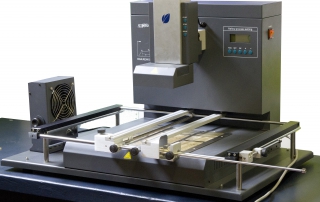

IR BGA Machine

FULLY INFRARED SYSTEM FOR QUICK AND CONTROLLED BGA REWORK. No need for nozzles, equipped with infrared as the directional component . It uses infrared sensors, non-contact detection for real-time temperature. To prevent heat transfer to neighboring components you can use aluminum foil, supplied in the kit, to reflect heat. Included side camera with high definition LED lighting to see the melting process of the balls on the component . Success rate of the profile of re-work close to 100% .

BGA REWORK Machines

To ensure even heat distribution and right peak temperature, realizes reliable lead-free soldering. The BGA system model 2120 uses closed loop sensor control, the top heater uses hot air heating, sectional hot air for BGA, infrared heating part for complete PCB to prevent PCB from being distorted. 2120 System uses 60*60MM optical lens to align components. Alignment for large BGA can still be seen clearly. Using motor to control align glass, placing the small plate for chips above it. The frame structure PCB can place special supporting rods. The bottom supporting rods are connected with landscape orientation rods to make sure accordance when place PCB. Adopts rocker, linear precision orbit and precision silk pole to control the adjustment of X,Y, Z. Using motor to control rough and fine adjustment. Except using manual fine adjustment of X, Y, in chip fine alignment, 2120 can automatically control the chip pick up, chip placement, glass movement, reflow control, heater movement, chip de-soldering etc. which is unique in lead-fee rework systems.

Rework complete Services

RETRONIX

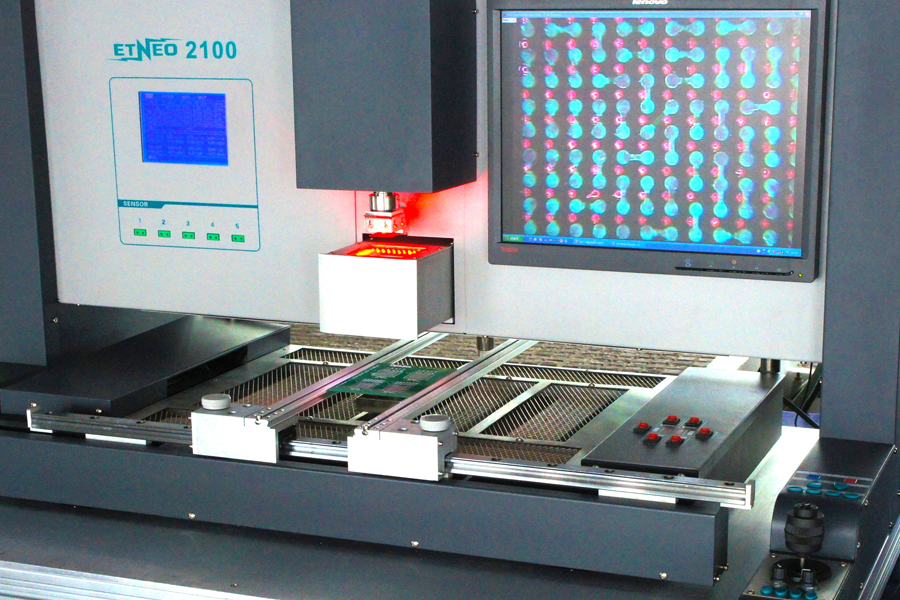

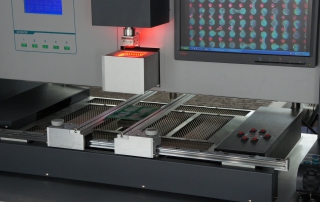

Etneo Italy offers an advanced Complete Rework even for a few pieces of REBALLING and REWORK PROCESS CONTROL WITH X-RAY

- Process: 24 hours baking component to eliminate contamination

- Deballing balls with cleaning pads

- Reballing of ball grid array with process by laser at low temperature

- Mechanical control with 3D machine

- Control X-rays for BGA Welding Vs on board

- Components Supply reel or trays – packaging under vacuum