Applications video

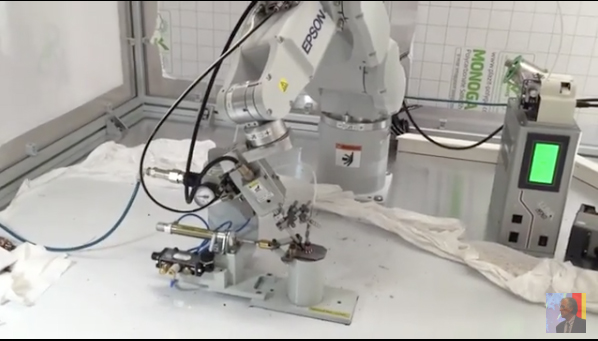

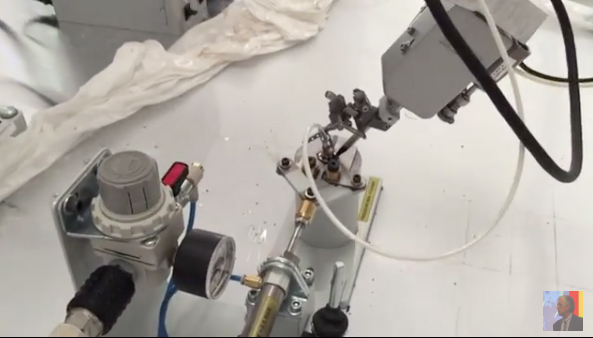

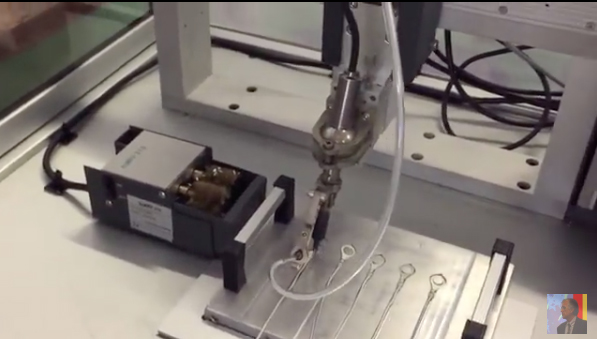

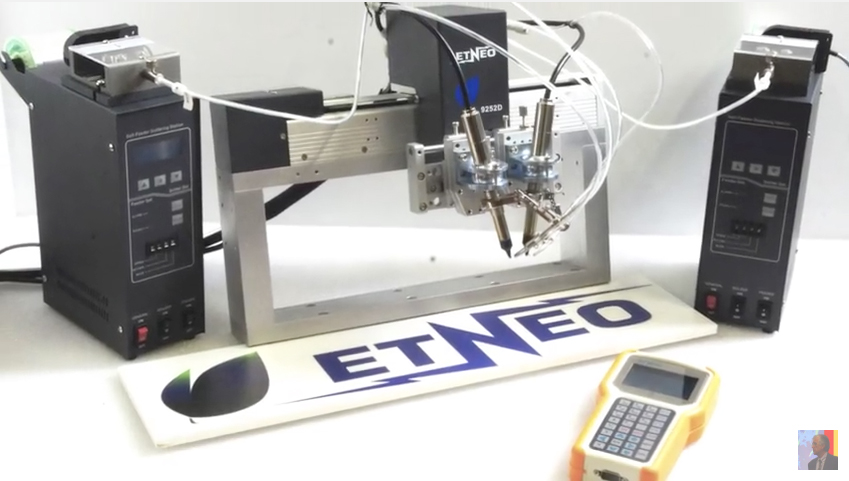

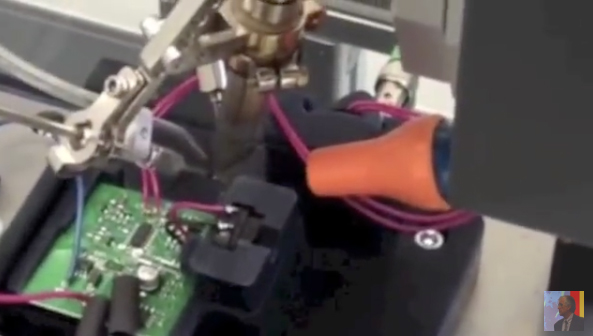

ANTHROPOMORPHOUS ROBOT

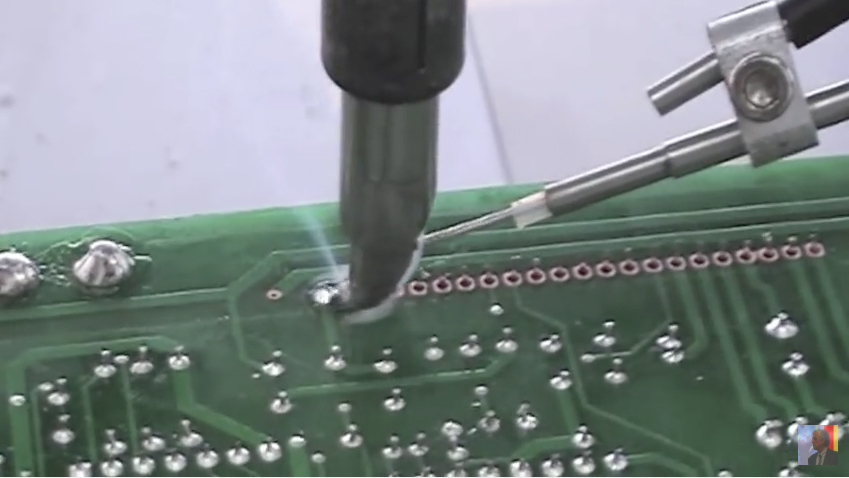

Custom application, our client had the required ‘to solder 8 points circularly arranged in 3D. The freedom ‘of movement of a 6-axis anthropomorphic (in this case of Epson), allowed Etneo to consolidate a process of soldering reliable and repetitive. (video realized during the construction of the solder cell)

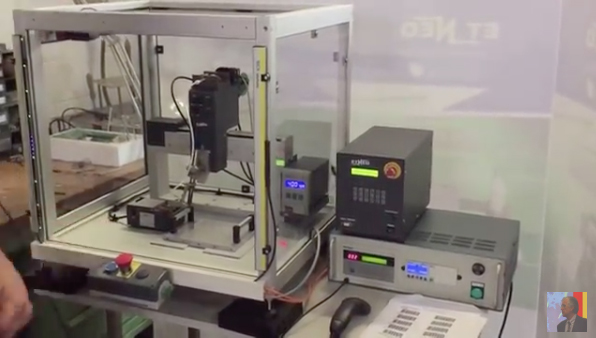

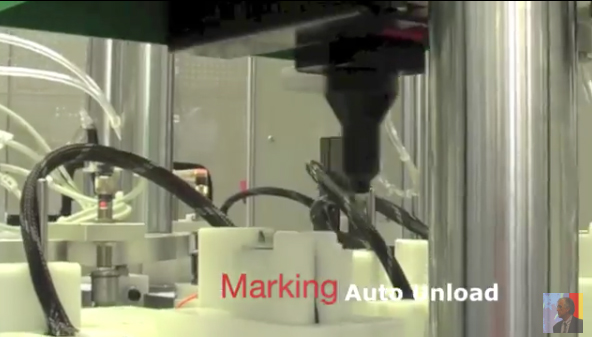

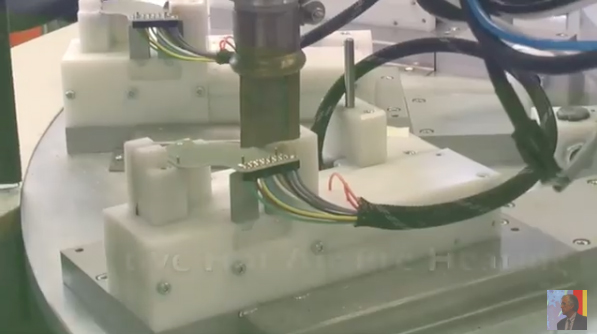

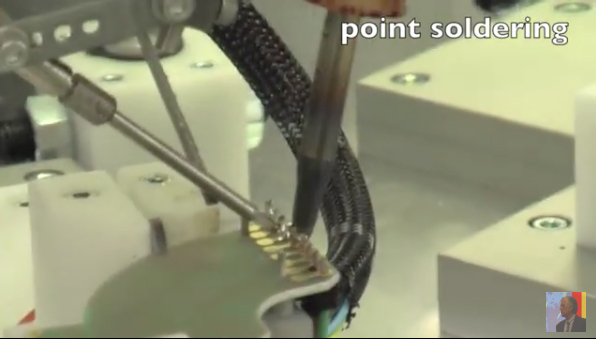

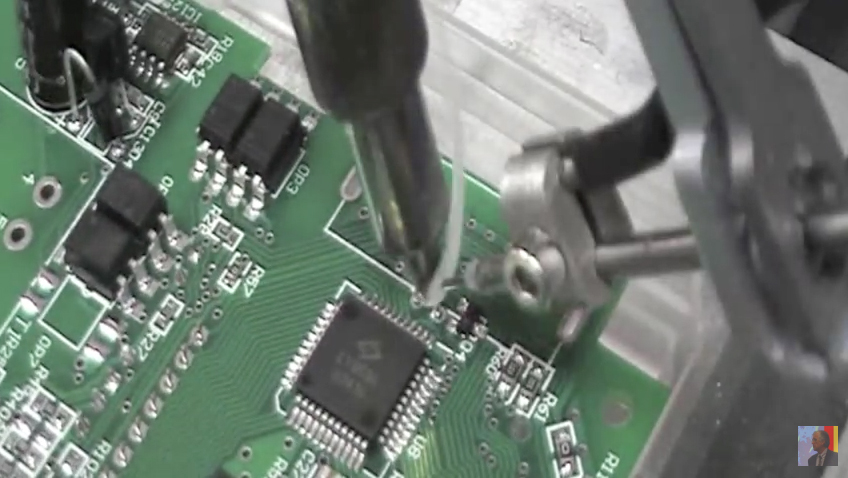

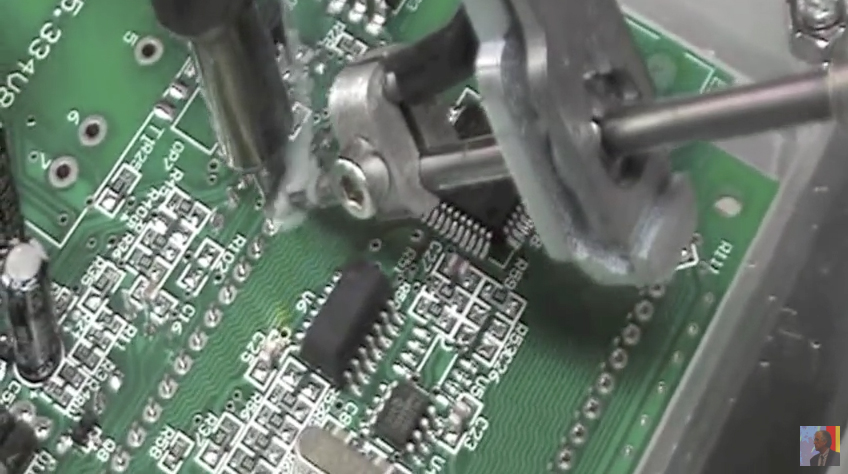

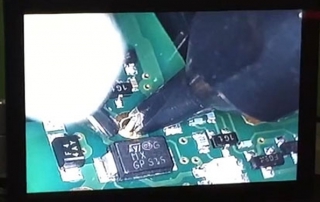

SOLDERING AUTOMATION + CUSTOM FUNCTIONS

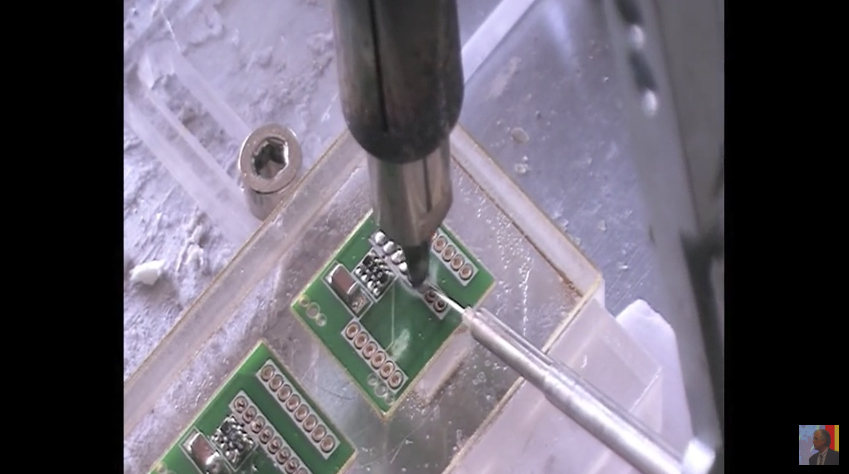

Wiring with pcb with 9 points to be soldered – Automotive sector – Automation made in cooperation with an Integrator. Applied functions: Load parts, pre-heating hot air to reduce the cycle time of soldering, type of solder point to point divided into three parts to increase productivity ‘, test continuity’ connection, marking, automatic unload.

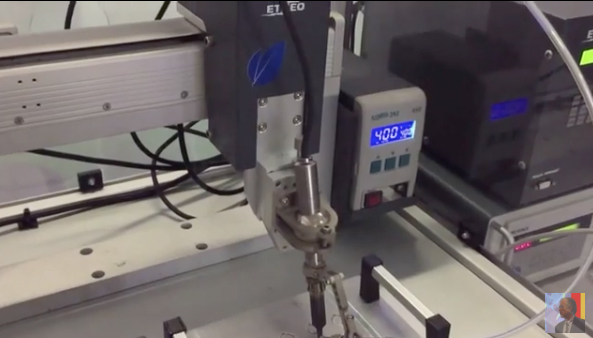

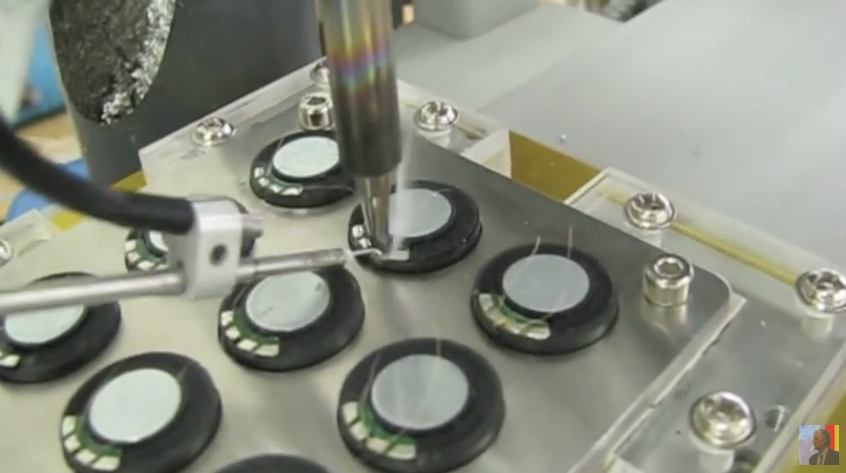

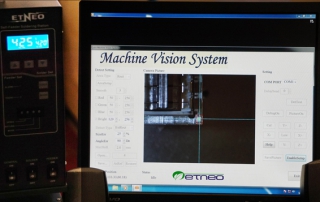

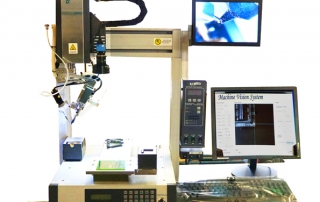

VISION TECHNOLOGY FOR INTEGRATED SOLDERING

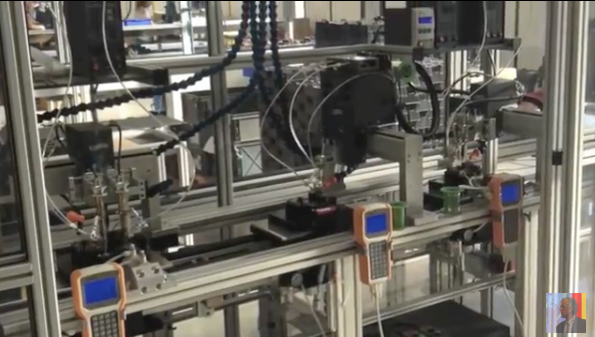

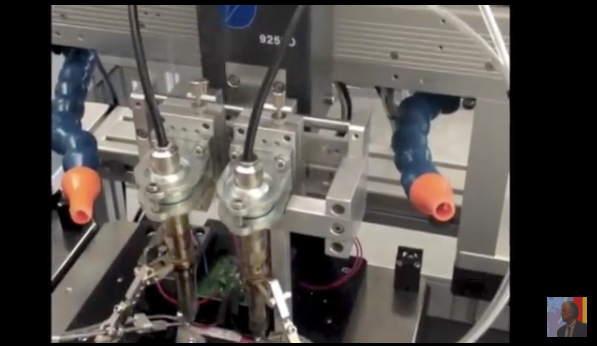

The below picture shows a part of an advanced assembly line for soldering spe-cial contacts on the PCB/wires and housing. Multiple systems of Etneo axes, each able to perform double simultaneously points solder. The Etneo systems integrate systems in some cases double – Two Iron Units – Two Wire feed-er – Two control units, in other cases replace the iron units with special tips, designed and built to solder multiple soldering points simultaneously. The Etneo robots are installed on conveyor, performing the solder on the moving pallets.